MATRIX

MATRIX

Matrix 1.0

Have you always been looking for a machine that cuts your boneless meat products in cubes, steaks or stripes? A machine that can do it all?

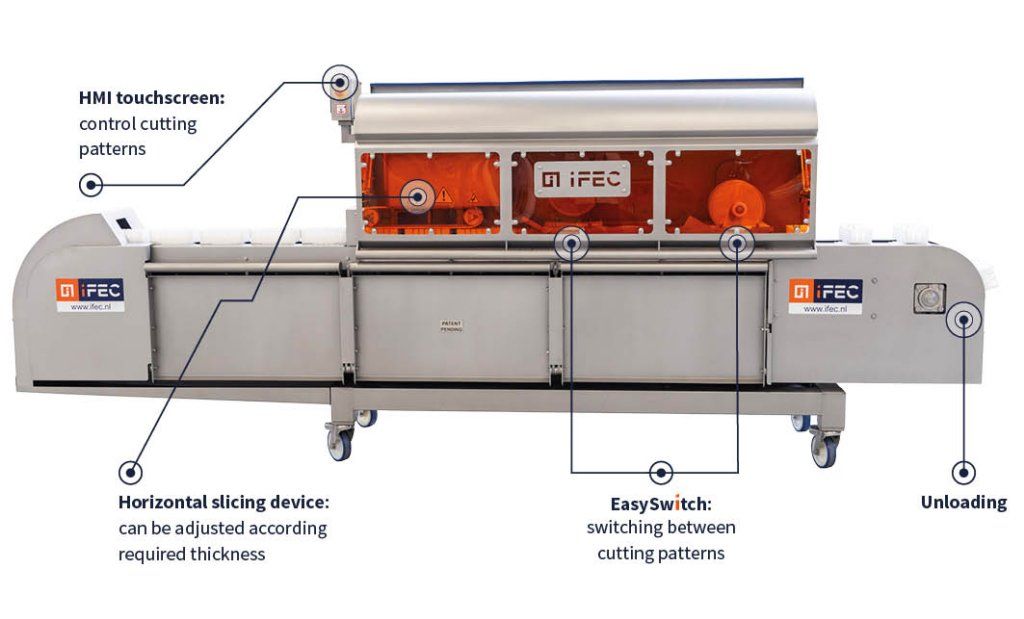

Meet the all new revolutionary MATRIX 1.0 by IFEC. The MATRIX concept is the only multifunctional boneless meat portioning machine available in the meat processing industry.

Changing the different cutting patterns can be done easily by and unique EasySwitch system. The EasySwitch system also allow you dismantle the cutting molds easily for cleaning.

The MATRIX 1.0 is the ideal machine if you need full flexibility combined with a minimum investment and using a minimum of floorspace. Either you already produce all kinds of boneless products such as diced or sliced products, or if you want to open new markets to supply market demands without investing in several equipment produce this automated the MATRIX 1.0 is your solution!

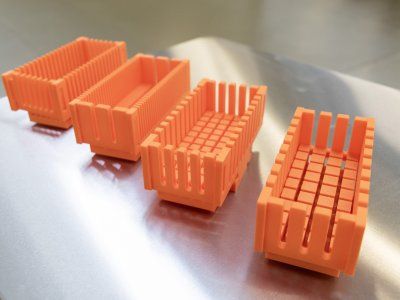

Another unique feature on the MATRIX is that IFEC can supply the cutting molds easily according your specifications. With using the most modern 3D printing techniques IFEC can easily make prototypes.

ONE MACHINE DOES IT ALL

The machine has been designed and engineered in a way that it can easily cut and portion boneless meats in different cutting patters such as dicing (cubes), horizontal slicing, vertical slicing and sliced and diced at the same time.

Capacity: | 3000 infeed products/hour |

Power: | 1.5 kW |

Input: | 400V – 480V 50 – 60Hz |

Weight: | 1100 kg |

Size (L x W x H): | 4200 x 760 x 1750 mm |

Key Benefits

-

Compact machine that can make different products

Compact machine that can make different products -

EasySwitch system to easily switch between different cutting patterns

EasySwitch system to easily switch between different cutting patterns -

Click off and on product molds

Click off and on product molds -

Endless flexibility

-

Integrated CIP (clean in place) system to meet the highest hygiene requirements

Integrated CIP (clean in place) system to meet the highest hygiene requirements -

The ideal machine if you need full flexibility combined with a minimum investment and using a minimum of floorspace

The ideal machine if you need full flexibility combined with a minimum investment and using a minimum of floorspace

Product Highlights

-

A dicer (it can make cubes in different sizes)

A dicer (it can make cubes in different sizes) -

A lengthwise slicer (it can make strips thick and thin)

A lengthwise slicer (it can make strips thick and thin) -

A horizontal slicer (it can either cut a top layer, butterfly or make thin steak slices)

A horizontal slicer (it can either cut a top layer, butterfly or make thin steak slices) -

A vertical slicer (different thickness and for example cut the breasttip triangle and slice the rest)

A vertical slicer (different thickness and for example cut the breasttip triangle and slice the rest) -

All these things can be done on the same machine. The blades can be put in or out position automatically, the product carriers can be exchanged easily by a easy click on system

All these things can be done on the same machine. The blades can be put in or out position automatically, the product carriers can be exchanged easily by a easy click on system