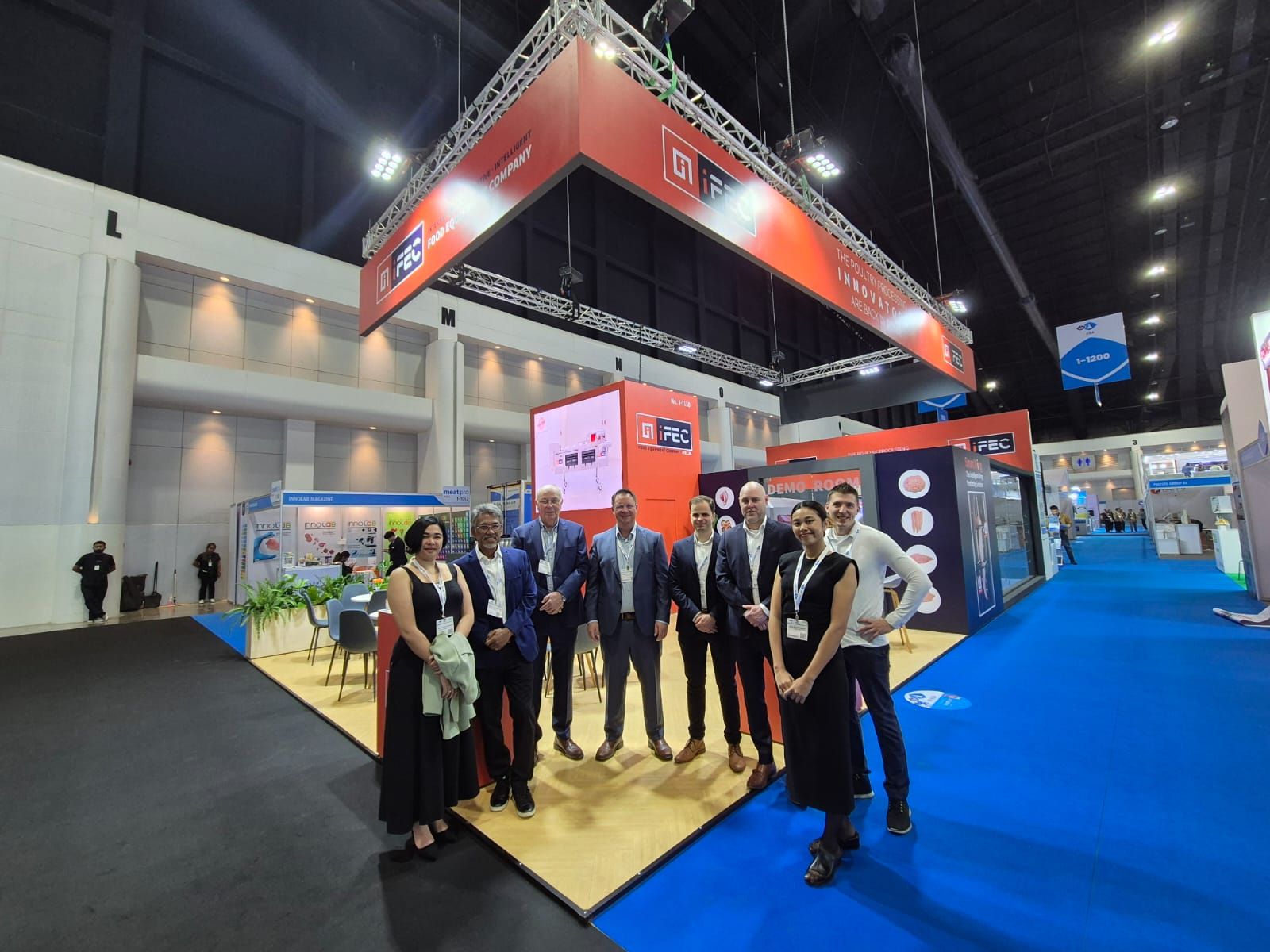

IFEC introduces SmartWing at the Asian market during VIV Asia 2025

IFEC, an innovative player in poultry processing, proudly introduced the SmartWing, the first AI-driven wing processing and portioning system in the industry. This cutting-edge solution was shown and demonstrated successfully at VIV Asia 2025 in Bangkok, Thailand, from March 12-14.

A New Standard in Wing Processing

The SmartWing revolutionizes poultry processing by combining AI-driven software, advanced camera technology, and precision engineering to deliver unmatched efficiency. Designed to optimize production while minimizing labor costs and reducing floorspace, the SmartWing provides poultry processors with actionable data for enhanced decision-making and future performance optimization.

Key Features of the SmartWing

The SmartWing utilizes advanced AI-powered inspection to identify defects such as blood spots, broken bones, and skin damage while ensuring superior wing portioning through high-tech camera systems that analyze each wing individually for precise anatomical cuts. The system automates grading and sorting by detecting and removing B-grade wings prior to processing. Additionally, it provides precision cutting and weighing by portioning wing tips, mid wings, and drumettes with exact accuracy before placing them onto an integrated tray system. With an optimized processing capacity of up to 8,000 wings per hour, it efficiently handles both left and right wings simultaneously. Fully compliant with the latest safety and hygiene standards, the SmartWing sets a new benchmark for poultry processing technology.

A Game-Changer for the Poultry Industry

Founder David Hazenbroek about the SmartWing: ‘The SmartWing is ideal for food service, retail, and the Asian market, offering higher-value specialty products with minimal operational disruption. By reducing handling, logistics, and manual labor by up to 80%, it significantly enhances efficiency and profitability.’

BACK MEAT HARVESTER FRONT HALVES

Besides the Smartwing, IFEC demonstraded The Back Meat Harvester Front Half edition. This machine has a capacity of 3000 pieces per hour. The front half carcasses are manually loaded onto specially designed cones, outfitted with a locking mechanism that ensures perfect alignment. Due to an extra pre-cut module, the back meat and remaining carcasses are automatically separated and unloaded. The final product is a beautiful piece of back meat suitable for further processing. Optionally, the back meat, including scapula bones, can be split into two pieces to transform it into a one-hand BBQ snack. The machine is equipped with stainless steel, non-ventilated washdown motors and gearboxes. It can be mechanically adjusted to operate with a wide range of upper back pieces sizes.

Operating and maintaining the back meat harvester is very easy, and with its small footprint, this is the perfect machine for upgrading your production.

Introducing IFEC: Innovation in Poultry Processing

Although IFEC is a young company, its founders bring decades of industry expertise. By combining their experience with a fresh, innovative approach, IFEC delivers specialized automated solutions that help poultry processors move beyond mass production and unlock new revenue streams. Their mission is to provide innovative, compact, and high-efficiency processing machines that maximize profitability, increase sustainability, and reduce dependency on labor.

Meet IFEC at IFFA 2025

In May 2025 IFEC will introduce SmartWing to theEuropean market at IFFA 2025. We invite industry professionals to experience this breakthrough technology firsthand.

Location: Messe Frankfurt, Germany

Booth: #9.1 – C40

May 3-8, 2025