SMARTWING

Meet the SmartWing: The first intelligent wing processing and portioning system in the industry.

Revolutionize your production process with cutting-edge AI technology, precision engineering, and unmatched efficiency. Boost A-grade output, minimize labor costs, and reduce floorspace, all while collecting actionable data to optimize your future performance.

Technology

The SmartWing expresses the level of innovation and implementation of the most advanced technics that IFEC stands for. It combines AI-driven software, advanced camera technology, and decades of industry expertise to transform your wing processing into a streamlined, high-performance operation.

product highlights

-

Excellent wing portioning by qualifying each wing individually with highly advanced camera technology, supported by Artificial Intelligence (AI).

Excellent wing portioning by qualifying each wing individually with highly advanced camera technology, supported by Artificial Intelligence (AI). -

Detects defects such as blood spots, broken bones and skin damage.

Detects defects such as blood spots, broken bones and skin damage. -

Automatically removes B-grade wings prior to processing.

Automatically removes B-grade wings prior to processing. -

Precision cuts for wing tips, mid wings, and drumettes, delivered onto an integrated tray system.

Precision cuts for wing tips, mid wings, and drumettes, delivered onto an integrated tray system. -

Weighs mid wings and drumettes individually and sorts them at designated stations.

Weighs mid wings and drumettes individually and sorts them at designated stations. -

Fully compliant with the latest safety regulations.

Fully compliant with the latest safety regulations.

key benefits

-

Get an optimal wing piece cut (anatomic joint cuts) and sell premium wing products. Ideal for food service industry, retail, Asian markets etc.

Get an optimal wing piece cut (anatomic joint cuts) and sell premium wing products. Ideal for food service industry, retail, Asian markets etc. -

Get an optimal wing piece cut (anatomic joint cuts) and sell premium wing products. Ideal for food service industry, retail, Asian markets etc.

Get an optimal wing piece cut (anatomic joint cuts) and sell premium wing products. Ideal for food service industry, retail, Asian markets etc. -

Reduce handling, logistics, distribution and human interference drastically (known cases from over 80%).

Reduce handling, logistics, distribution and human interference drastically (known cases from over 80%).

Size (L x W x H): | 5450 mm x 1350 mm x 2800 mm – 213” x 53” x 110” |

Weight: | ± 3000 kg / 6600 lb |

Power consumption: | 4,5 kW |

Capacity: | ± 8000 wings/h |

SMARTWING: Working principle

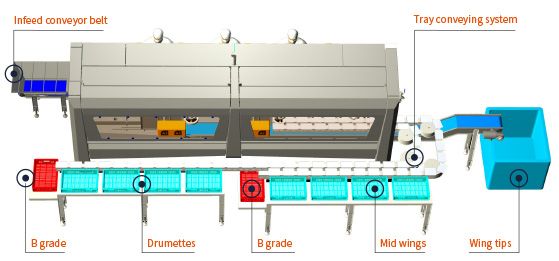

After this, the wings are entering the cutting stations that will portion the wings very precisely and individually. The wing pieces (mid wing without tip and the drumette) are dropped onto an integrated tray conveying system individually. The wing tip will drop on a (optional) conveyor belt and into a collecting bin.

The wing pieces on the integrated tray conveying system are being weighed very accurately and can be discharged at selected dropping stations.

Ready to revolutionize your wing processing? Contact us today to schedule a demo and see how the SmartWing can transform your operation.

smartwing-product

smartwing-product3