IFFA 2025, may 3-8

IFEC Showcases Cutting-Edge Poultry Processing Innovations at IFFA 2025

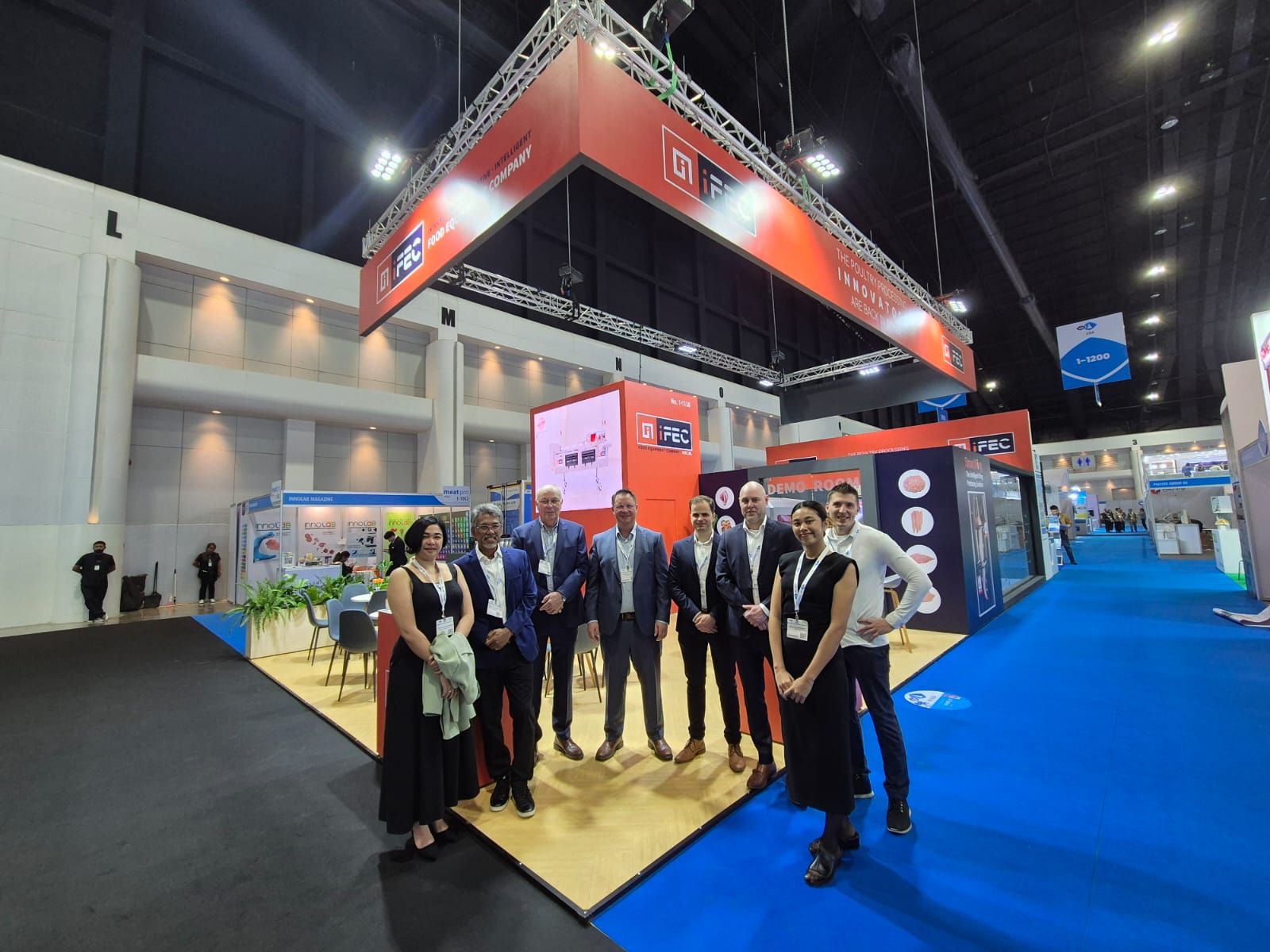

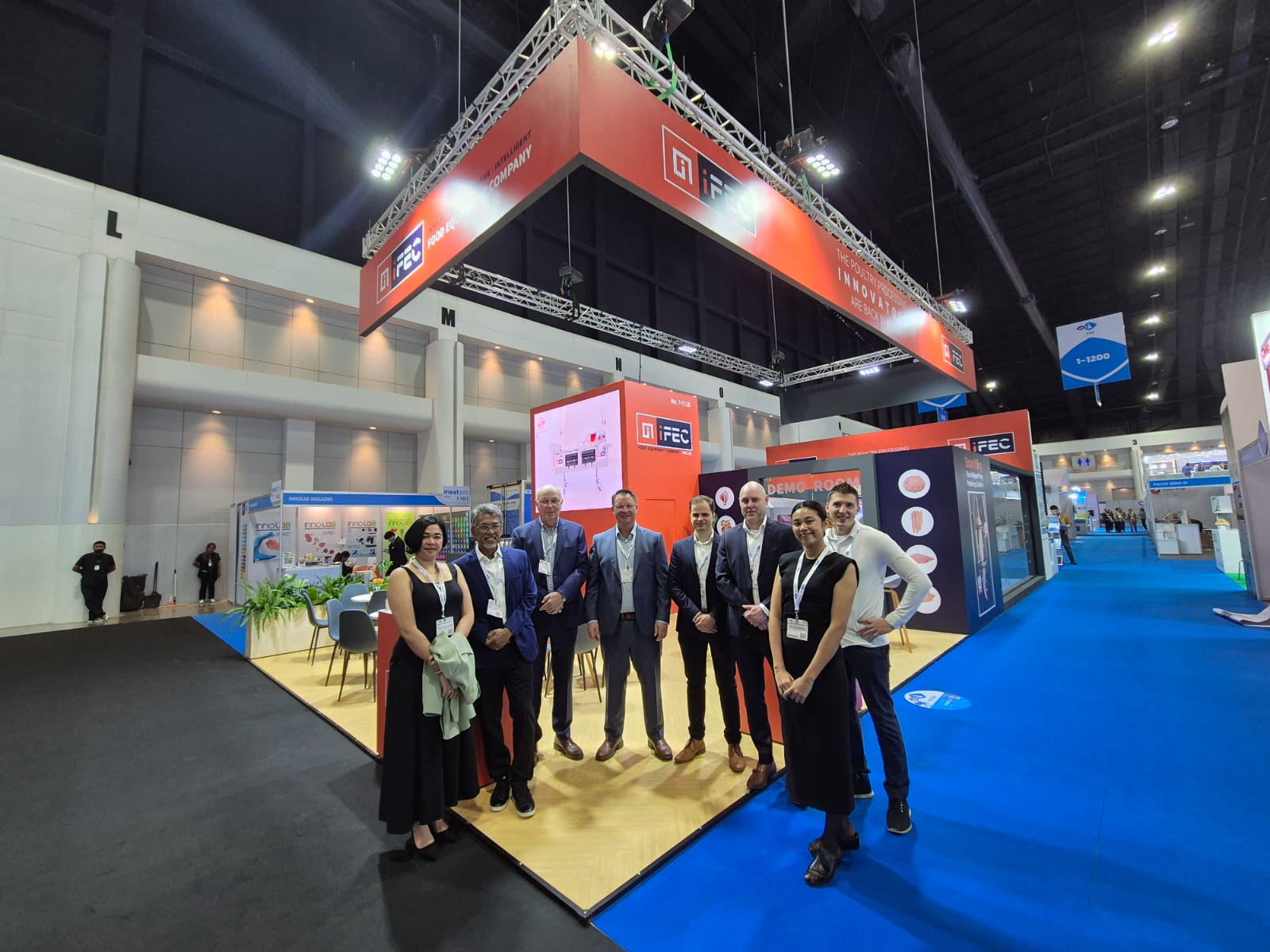

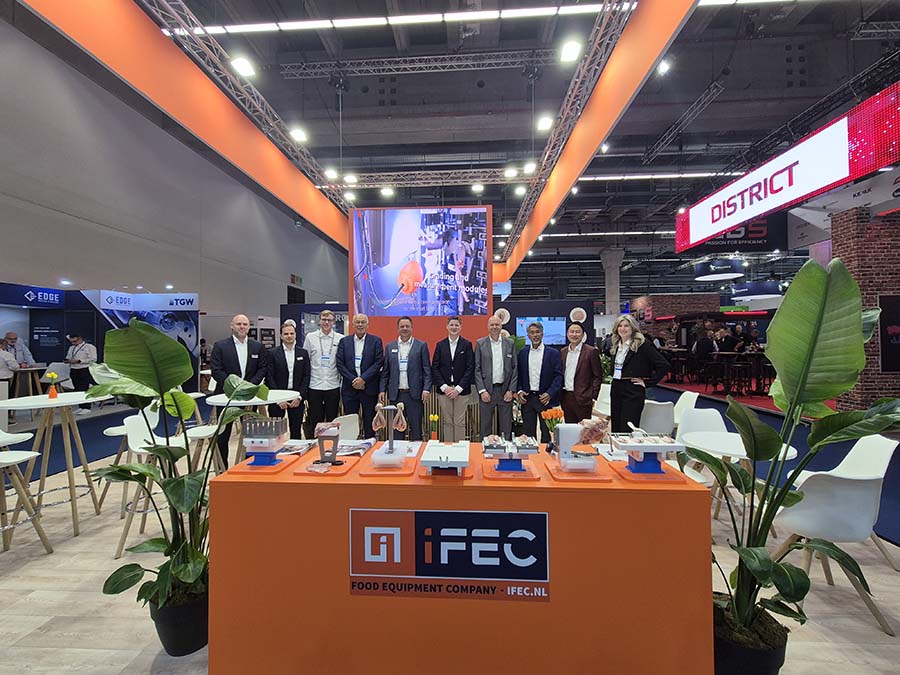

Oud-Beijerland, The Netherlands – May 13, 2025 – From May 3rd to 8th, IFEC proudly exhibited at the IFFA trade show in Frankfurt, Germany – the world’s leading trade fair for technology for meat and alternative proteins. The event welcomed over 63.000 visitors from 144 countries, all eager to experience the future of food processing driven by automation, artificial intelligence (AI), robotics, and sustainable protein alternatives.

-

iffa-20250503_095512

-

iffa-20250503_095633

-

iffa-20250503_104331

-

iffa-20250503_145713

-

iffa-20250503_162915

-

iffa-20250503_164434

-

iffa-20250505_165751

-

iffa-20250503_095438

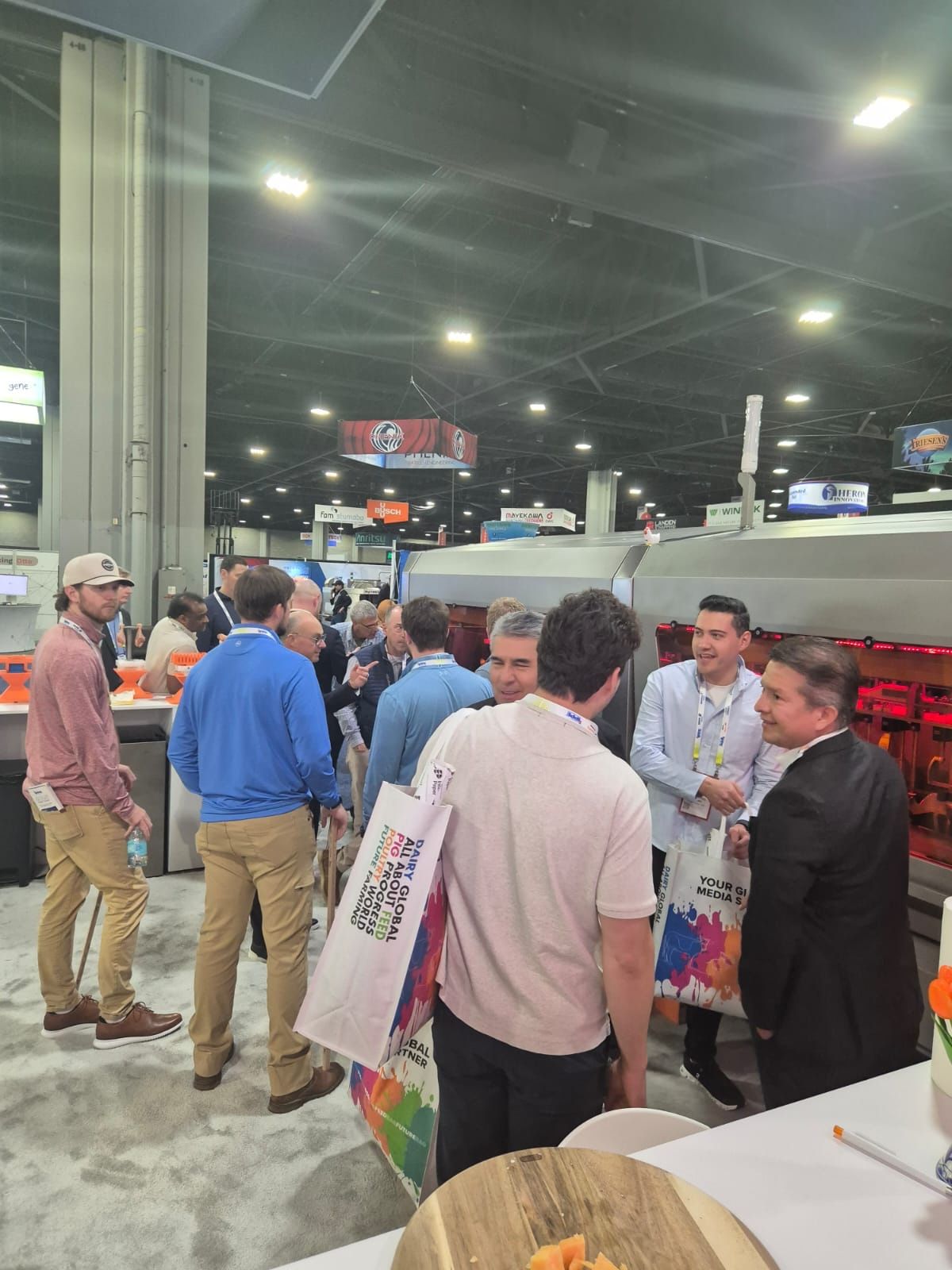

In IFEC’s dedicated Demo Room, visitors were given an exclusive look at four of our industry-leading poultry processing machines, with live demonstrations conducted daily.

One of the highlights was the European premiere of the SmartWing – the first intelligent wing processing and portioning system in the poultry industry. This groundbreaking solution merges AI-driven software, advanced camera technology, and decades of processing expertise to deliver high-performance, automated wing processing like never before.

Also featured was the MATRIX, the only multifunctional boneless meat portioning machine in the industry. With its unique EasySwitch system, operators can effortlessly change cutting patterns and dismantle molds for cleaning, making the MATRIX 1.0 the ideal solution for processors seeking maximum flexibility with minimal investment and floor space. Whether producing diced or sliced boneless products or entering new markets with a streamlined setup, the MATRIX 1.0 is a future-proof investment.

Visitors also experienced the Back Meat Harvester – Caps Edition, which handles up to 6.000 pieces per hour. The upper backs are manually loaded onto specially designed cones. The back meat and remaining upper backs are automatically separated and unloaded. The final product is a beautiful piece of back meat suitable for further processing.

Another standout on display was the Mid Wing Splitter – Split mid wings are becoming more and more popular around the world, because they are a perfect one hand snack. That’s why IFEC has developed an automatic mid wing splitter. The mid wing splitter has a stunning capacity of 7200 wings per hour and can handle a wide variety of anatomically cut mid wing sizes.

“We welcomed a large number of international visitors to our booth at IFFA,” said Cesar van Kerchove of IFEC. “There was great interest in our live demonstrations, and the enthusiasm around our innovations was overwhelming.”

Next Stop: Warsaw!

IFEC continues the momentum at Ptak Warsaw Expo, November 25–27, in Warsaw, Poland.

We look forward to connecting with even more industry professionals and showcasing what’s next in poultry processing.

Stay tuned for more updates – and we hope to see you in Warsaw!

For more information, please contact:

IFEC

Röntgenstraat 18

NL-3261 LK Oud-Beijerland

The Netherlands

Email: info@ifec.nl